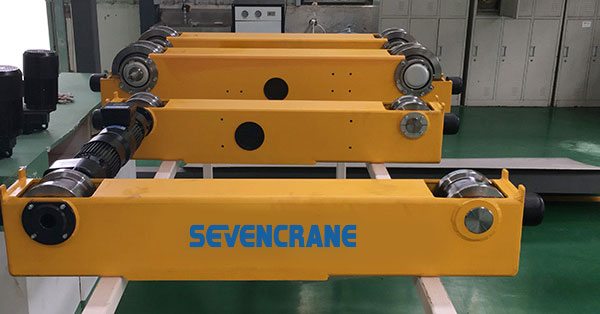

End carriages are an important part of the overhead crane system. They are responsible for supporting the bridge and hoist, which makes them essential in ensuring that the crane is functional and performs its task as expected, mainly in the industrial sector.

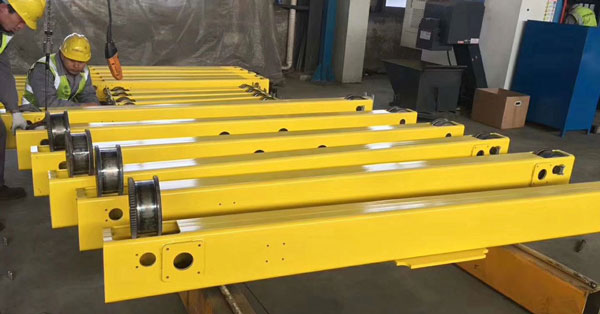

There are 14 production steps involved in the creation of an end carriage. These steps highlight the careful planning, exceptional workmanship, and attention to detail that goes into making a high-quality end carriage.

Step 1: Cutting

The first step involves cutting the steel to size, making sure to follow the necessary specifications.

Step 2: Drilling

Next, the end carriage is drilled to prepare for the assembly stage.

Step 3: Assembling the frame

The frame of the carriage is welded together with precision and accuracy.

Step 4: Making shafts

The shafts of the end carriage are made, ensuring they are strong and can support the weight of the bridge and hoist.

Step 5: Machining

The surface of the end carriage is machined to create a smooth finish.

Step 6: Making gears

Gears are made and installed, which is important for the smooth running of the crane.

Step 7: Installing the bearings

Bearings are installed to aid in the movement of the end carriage.

Step 8: Painting

The end carriage is painted in a coat of primer to ensure it is protected from rust.

Step 9: Final assembly

All the different components of the end carriage are assembled together, ensuring that they all work in conjunction with each other.

Step 10: Electrical Wiring

The electrical wiring is installed, ensuring that the end carriage is ready to now work with the crane system.

Step 11: Testing

The end carriage is tested to ensure that it can perform its intended function.

Step 12: Quality Control

The end carriage is checked for quality to ensure that it meets all the required standards.

Step 13: Packaging

The end carriage is also packaged in premium packaging, ensuring safe transport and arrival at its intended location.

Step 14: Shipping

The end carriage is then shipped to its final location, ready to be installed and put to use.

In conclusion, the production steps for end carriages showcase the exceptional workmanship that goes into making a high-quality product. The attention to detail in the different stages ensures that the end product is functional, durable, and of superior quality, which, in turn, ensures the end crane is up to the task it has been designed for.