-

1. Raw materials:

According to client requirements for crane hook, proper raw material will be prepared.

-

2. Steel testing:

Before production, chemical composition & chemical composition of raw materials is carried out.

-

3. Steel marking and blanking:

Raw material is cut into certain sizes and weights accordingly.

-

4. Heating (including tempering):

Raw materials is heated with temperature necessary.

-

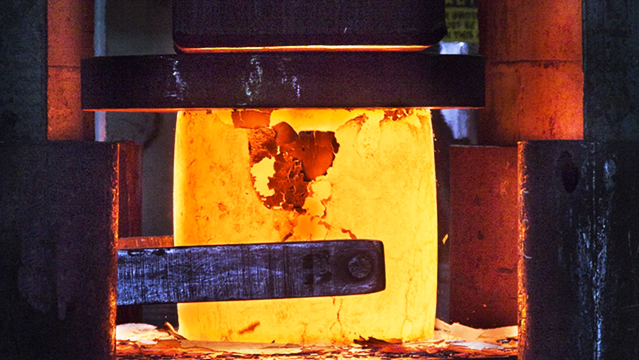

5. Forging:

With complete forging equipment, material temperature and forging process is monitored in real time.

-

6. Forging inspection:

Preliminary inspection for forging blanks–mainly appearance and size inspection. Defects like cracks are not allowed. Margin of blanks is qualified.

7. Heat preservation and normalizing after forging:

Refining crystal grains, uniform organization, and eliminate internal stress. Improve defects: widmanstatten, coarse grains and other overheating defects and banded structure. Prepare for the final heat treatment.

-

8. Rough machining:

Rough machining with finishing allowance

-

9. Final Heat treatment:

Normalizing, quenching and tempering, quenching–Comprehensive process to improve internal structure and mechanical properties.

Heating forging to a certain temperature, holding for certain time, cooling down at predetermined speed.

This process can eliminate internal stress, prevent deformation during machining, and adjust hardness to facilitate cutting.

-

10.Finishing machining:

By CNC machining center, dimensional accuracy and smoothness of the products are fully achieved according to production drawing.

-

11.Product appearance inspection :

Carry out Ultrasonic flaw detection (UT)

Magnetic particle flaw detection (MT)

Hardness inspection

Carburization inspection

12. Assembly and mechanical performance test:

After assembly for hook group, it will take pull/tension test.

Mechanical properties of forgings–yield, tensile, impact, and metal equivalence tests.

-

13. Surface treatment and packaging:

After quality inspection, anti-rust spray paint will be applied before packing and shipment

-

14. Loading and delivery:

With proper package for shipping, finished products are ready for shipping in warehouse.