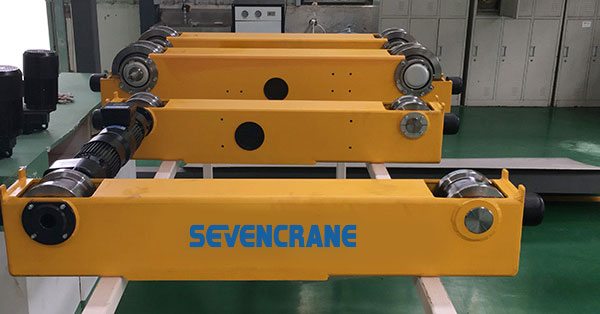

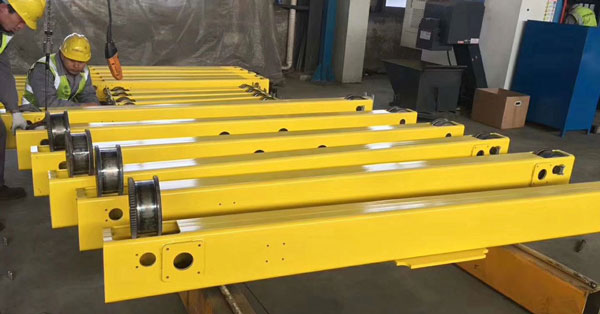

Quality control is an essential part of the production process, especially when it comes to end carriage. This crucial component of an overhead crane system plays an important role in its smooth operation, and any flaw or defect can have serious consequences. Therefore, it is imperative to have strict quality control measures in place to ensure that the end carriage meets all the necessary standards and requirements.

One of the first steps in quality control is to define the specifications and tolerances for the end carriage. This involves determining the material requirements, dimensions, weight, load capacity, and other technical details. These specifications serve as a blueprint for the production process and ensure that all components are consistent and compatible with each other.

Once the specifications have been established, the next step is to monitor the production process and perform various tests and inspections at different stages. For example, workers can use measuring tools to check the dimensions of the end carriage and verify that they are within the specified range. They can also perform load tests to ensure that the carriage can handle the required weight without bending or breaking.

In addition, there should be a system in place for detecting and resolving any quality issues that arise. This may involve conducting internal audits, reviewing customer feedback, and taking corrective action whenever necessary. It is important to address quality issues promptly and thoroughly to prevent them from becoming more serious or widespread.